Metal Preparation

As with acid etching, the metal has to be thoroughly cleaned prior to being processed. Each piece of metal is scrubbed, cleaned, and cleansed using water pressure and a mild solvent. The process eliminates oil, contaminants, and tiny particles. This is necessary to provide a smooth clean surface for the application of the photoresist film to securely adhere.

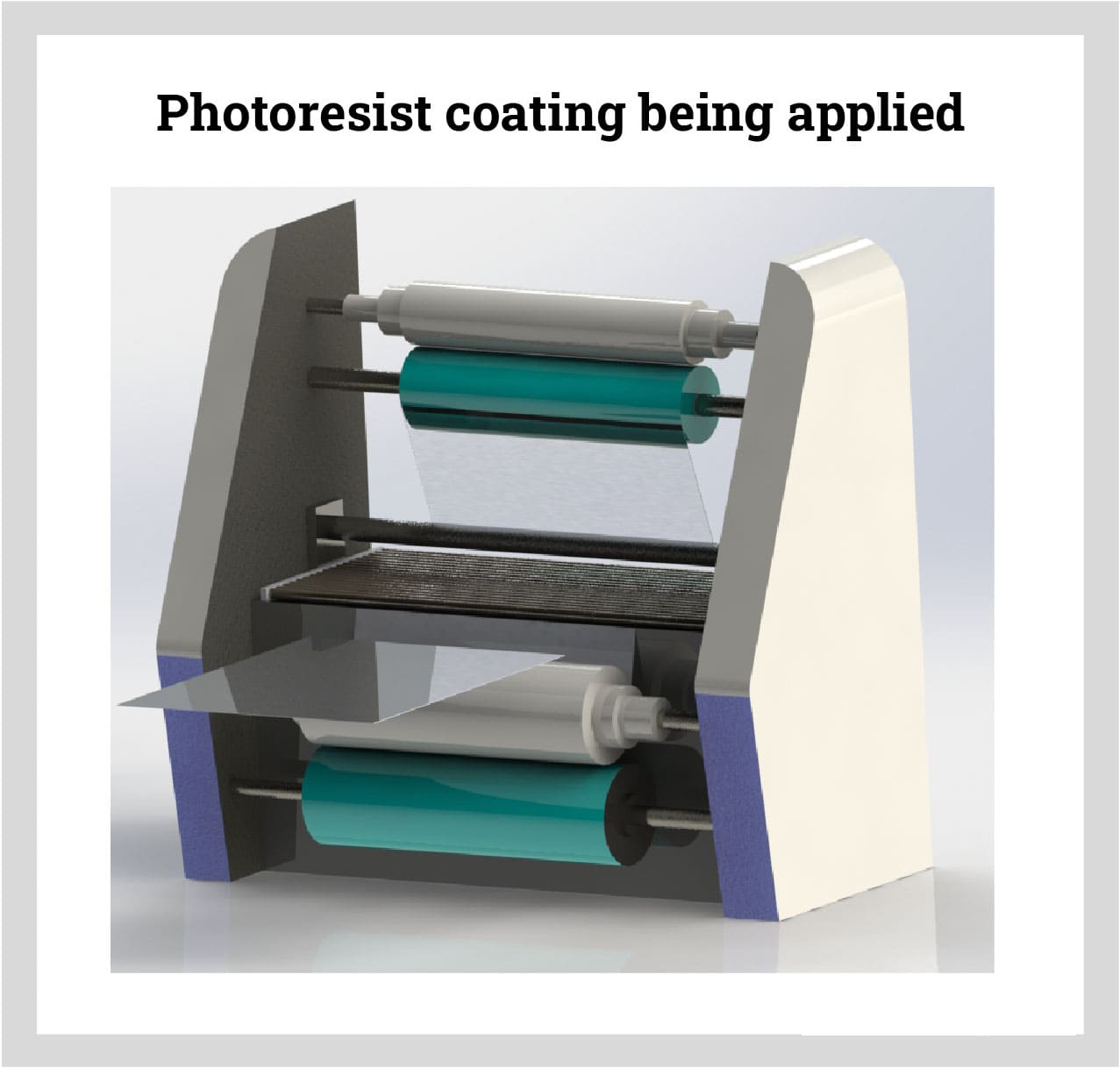

Laminating Metal Sheets with Photoresistant Films

Lamination is the application of the photoresist film. The metal sheets are moved between rollers that coat and evenly apply the lamination. To avoid any undue exposure of the sheets, the process is completed in a room lit with yellow lights to prevent UV light exposure. Proper alignment of the sheets is provided by holes punched in the edges of the sheets. Bubbles in the laminated coating are prevented by vacuum sealing the sheets, which flattens the layers of laminate.

To prepare the metal for photochemical metal etching, it must be thoroughly cleaned to remove oil, contaminants, and particles. Each piece of metal is scrubbed, cleaned, and washed with a mild solvent and water pressure to ensure a smooth, clean surface for the application of the photoresist film.

The next step is lamination, which involves applying the photoresist film to the metal sheets. The sheets are moved between rollers to evenly coat and apply the film. The process is carried out in a yellow-lit room to prevent UV light exposure. Holes punched in the edges of the sheets provide proper alignment, while vacuum sealing flattens the layers of laminate and prevents bubbles from forming